Expanding a plastic bag manufacturing business requires strategic investments in high-performance machinery that enhances productivity, reduces costs, and ensures consistent quality. Choosing the right equipment can make the difference between staying stagnant and achieving significant growth. In this blog, we explore how Mita Machinery’s advanced plastic bag manufacturing machines help businesses scale efficiently.

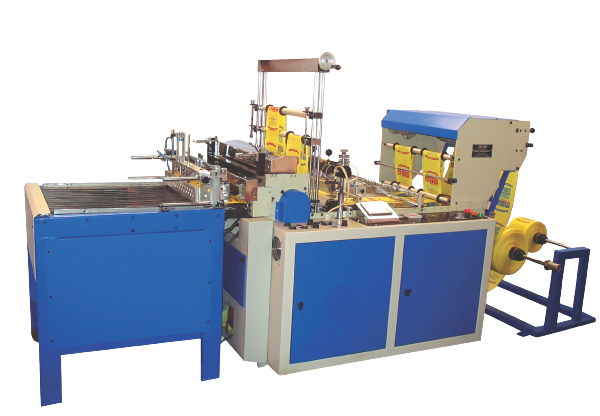

Graphic Suggestion: A visual representation of business growth linked to modern plastic bag manufacturing equipment, placed on the right side.

Business expansion in the plastic bag industry demands a combination of technological upgrades, efficiency improvements, and sustainability measures.

As demand increases, manufacturing speed must keep up. Investing in fully automated, high-speed plastic bag machines can significantly enhance output capacity.

Benefits:

Graphic Suggestion: A side-by-side comparison of manual vs. automated plastic bag production, placed on the left side.

Scaling your business means catering to a broader market. Mita Machinery offers multi-functional machines that allow customization for different bag types, including:

Graphic Suggestion: A diagram showcasing different bag types and their applications, placed on the right side.

As production scales up, so do operational costs. Investing in energy-efficient machines ensures sustainable growth while keeping expenses under control.

Key Features of Mita Machinery’s Energy-Efficient Models:

Graphic Suggestion: A comparison chart displaying energy consumption before and after upgrading to energy-efficient models, placed on the left side.

A growing business must ensure that quality remains consistent despite increased production levels. AI-driven defect detection and real-time monitoring in Mita Machinery’s systems ensure:

Graphic Suggestion: An infographic illustrating how AI-driven quality control works in plastic bag manufacturing, placed on the right side.

Scaling is not just about increasing production; it’s about expanding into new markets with the right product offerings. Mita Machinery helps businesses diversify by offering machines designed for:

Graphic Suggestion: A world map showing potential expansion markets and industries that use Mita Machinery’s products, placed on the left side.

Businesses that invest in scalable, sustainable, and cost-effective machinery are better positioned for long-term success. Future trends in the industry include:

Graphic Suggestion: A timeline forecasting the evolution of plastic bag manufacturing technologies, placed on the right side.

Scaling a plastic bag manufacturing business requires the right blend of automation, customization, energy efficiency, and quality control. Mita Machinery’s cutting-edge solutions empower businesses to expand production while maintaining quality and profitability.

Are you ready to take your plastic bag manufacturing business to the next level? Contact Mita Machinery today to explore tailored solutions for your growth strategy.

Hitesh Varyani

A results-driven technology consultant specializing in IT strategy and software solutions, enabling businesses to optimize processes and achieve measurable growth. Skilled in aligning technology with business objectives to deliver sustainable, high-impact results.

MITA MACHINERY is one of the few company in India to offer both LDPE/PP/BOPP BAG making machine and LAMINATE POUCH making machine.

Don’t miss our future updates! Get Subscribed Today!

©2025. Mita Machinery. All Rights Reserved.