As global awareness of plastic waste pollution grows, businesses and consumers are seeking sustainable alternatives. Among the most discussed solutions are recyclable plastics and biodegradable plastics—two distinct approaches to addressing environmental concerns. Understanding their differences, advantages, and challenges is crucial for making informed choices in plastic bag manufacturing.

Graphic Suggestion: A side-by-side comparison infographic showing recyclable vs. biodegradable plastics placed on the right side.

Recyclable plastics are designed to be reprocessed and reused multiple times, reducing the need for virgin plastic production. These plastics undergo mechanical or chemical recycling, transforming them into new plastic products or packaging materials.

Key Features:

Challenges:

Applications:

Graphic Suggestion: A flowchart illustrating the recycling process of plastic, placed on the left side.

Biodegradable plastics break down into natural elements, such as water and carbon dioxide, through microbial action. These plastics are often derived from plant-based sources and are engineered to decompose in specific environments.

Key Features:

Challenges:

Applications:

Graphic Suggestion: An illustration showing the decomposition stages of biodegradable plastics, placed on the right side.

Both options have their place in sustainable plastic manufacturing. While recyclable plastics extend the lifecycle of materials, biodegradable plastics reduce long-term environmental impact. Here’s a comparative analysis:

Feature | Recyclable Plastics | Biodegradable Plastics |

Material Source | Petroleum-based & bio-based | Primarily bio-based |

End-of-Life Disposal | Recycled & repurposed | Decomposed naturally |

Infrastructure Needed | Recycling plants | Composting facilities |

Sustainability Impact | Reduces plastic waste | Reduces microplastic pollution |

Graphic Suggestion: A comparison table visually highlighting the key differences between the two options, placed on the left side.

As industries move towards a circular economy, a combination of recyclable and biodegradable solutions may offer the most sustainable future. Emerging trends include:

Graphic Suggestion: A timeline predicting advancements in recycling and biodegradable plastic technologies, placed on the right side.

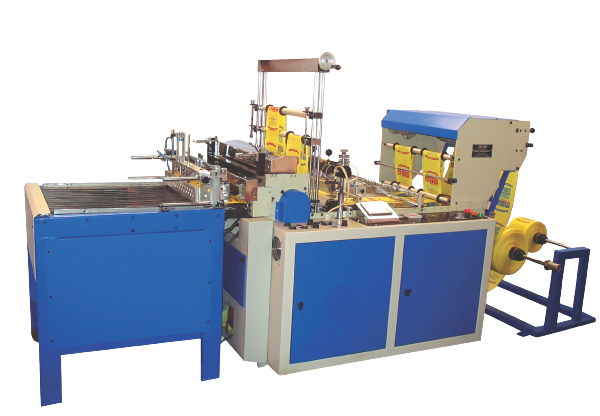

Choosing between recyclable and biodegradable plastics depends on industry needs, environmental goals, and available waste management systems. Mita Machinery offers cutting-edge solutions in plastic bag manufacturing, supporting both recyclable and biodegradable production methods. Our goal is to help businesses transition towards more sustainable packaging.

Are you ready to adopt eco-friendly plastic bag manufacturing? Contact Mita Machinery today to explore our innovative solutions.

Hitesh Varyani

A results-driven technology consultant specializing in IT strategy and software solutions, enabling businesses to optimize processes and achieve measurable growth. Skilled in aligning technology with business objectives to deliver sustainable, high-impact results.

MITA MACHINERY is one of the few company in India to offer both LDPE/PP/BOPP BAG making machine and LAMINATE POUCH making machine.

Don’t miss our future updates! Get Subscribed Today!

©2025. Mita Machinery. All Rights Reserved.