The global demand for plastic packaging continues to rise, but so do concerns over its environmental impact. Businesses across industries are now seeking sustainable alternatives to conventional plastic bags. Mita Machinery is at the forefront of this transition, providing eco-friendly plastic bag manufacturing solutions that balance efficiency with environmental responsibility.

The plastic industry is undergoing a transformation due to increasing regulations, consumer awareness, and corporate responsibility initiatives. Traditional plastic bags contribute significantly to environmental pollution, making it imperative for manufacturers to adopt greener production techniques.

Key Sustainability Challenges:

Mita Machinery integrates state-of-the-art technology in its machines to promote sustainability while maintaining high production standards. Our commitment to green solutions includes energy-efficient technology, material optimization, and waste reduction strategies.

Our advanced bag-making machines support biodegradable plastic materials like PLA (Polylactic Acid), PBAT (Polybutylene Adipate Terephthalate), and PHA (Polyhydroxyalkanoates). These materials decompose naturally within a few months, unlike traditional plastics that take hundreds of years to break down.

Benefits:

Our machines are designed for lower energy consumption, reducing the carbon footprint of the manufacturing process. They feature:

Impact:

By using multi-layer co-extrusion technology, our machines enable manufacturers to reduce material usage while enhancing the durability of plastic bags.

Advantages of Multi-Layer Technology:

Applications:

The industry is rapidly shifting towards a circular economy, where plastic waste is minimized through innovative recycling and reprocessing techniques.

Upcoming Trends:

Sustainability is no longer an option but a necessity for plastic bag manufacturers. Mita Machinery is committed to offering advanced, eco-friendly plastic bag manufacturing machines that help businesses reduce their environmental impact without compromising efficiency. Our innovations in biodegradable plastics, energy efficiency, and multi-layer film technology ensure that your business stays ahead in the global sustainability movement.

Are you ready to embrace sustainable plastic bag production? Contact Mita Machinery today to explore our range of eco-friendly manufacturing solutions.

Hitesh Varyani

A results-driven technology consultant specializing in IT strategy and software solutions, enabling businesses to optimize processes and achieve measurable growth. Skilled in aligning technology with business objectives to deliver sustainable, high-impact results.

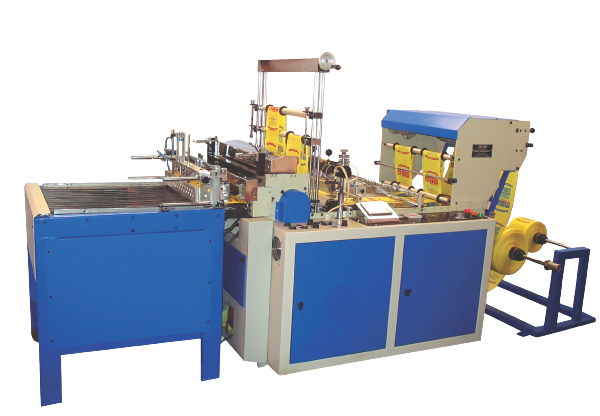

MITA MACHINERY is one of the few company in India to offer both LDPE/PP/BOPP BAG making machine and LAMINATE POUCH making machine.

Don’t miss our future updates! Get Subscribed Today!

©2025. Mita Machinery. All Rights Reserved.