Understanding Different Types of Plastic Bag Machines

Understanding Different Types of Plastic Bag Machines

Plastic bag manufacturing has evolved significantly over the years, with various types of machines designed to meet different production needs. Whether for retail, food packaging, or industrial applications, selecting the right plastic bag machine is crucial for efficiency, quality, and cost-effectiveness. In this guide, we’ll explore the different types of plastic bag machines and their applications.

1. Extrusion Machines

Extrusion machines are the foundation of plastic bag production. These machines process raw plastic materials, such as polyethylene (PE) and polypropylene (PP), by melting and shaping them into thin films. The extruded plastic film is then used for further processing into bags. The quality of extrusion affects the strength, flexibility, and durability of the final bag product.

Key Features:

- Adjustable thickness for various bag types.

- High-speed production for bulk processing.

- Energy-efficient models available for sustainable production.

Applications:

- Plastic shopping bag films

- Garbage bag films

- Industrial packaging films

2. Printing Machines

Printing machines add branding, logos, and product details to plastic bags. They use techniques like flexographic and gravure printing to ensure high-quality prints with vibrant colors and durable ink adhesion. Flexographic printing is preferred for large-scale production, while gravure printing is used for premium packaging due to its high resolution.

Key Features:

- Supports multi-color printing.

- High-speed and low-cost bulk printing options.

- Ink drying technology to prevent smudging.

Applications:

- Retail store bags with logos

- Branded food packaging bags

- Custom-designed promotional bags

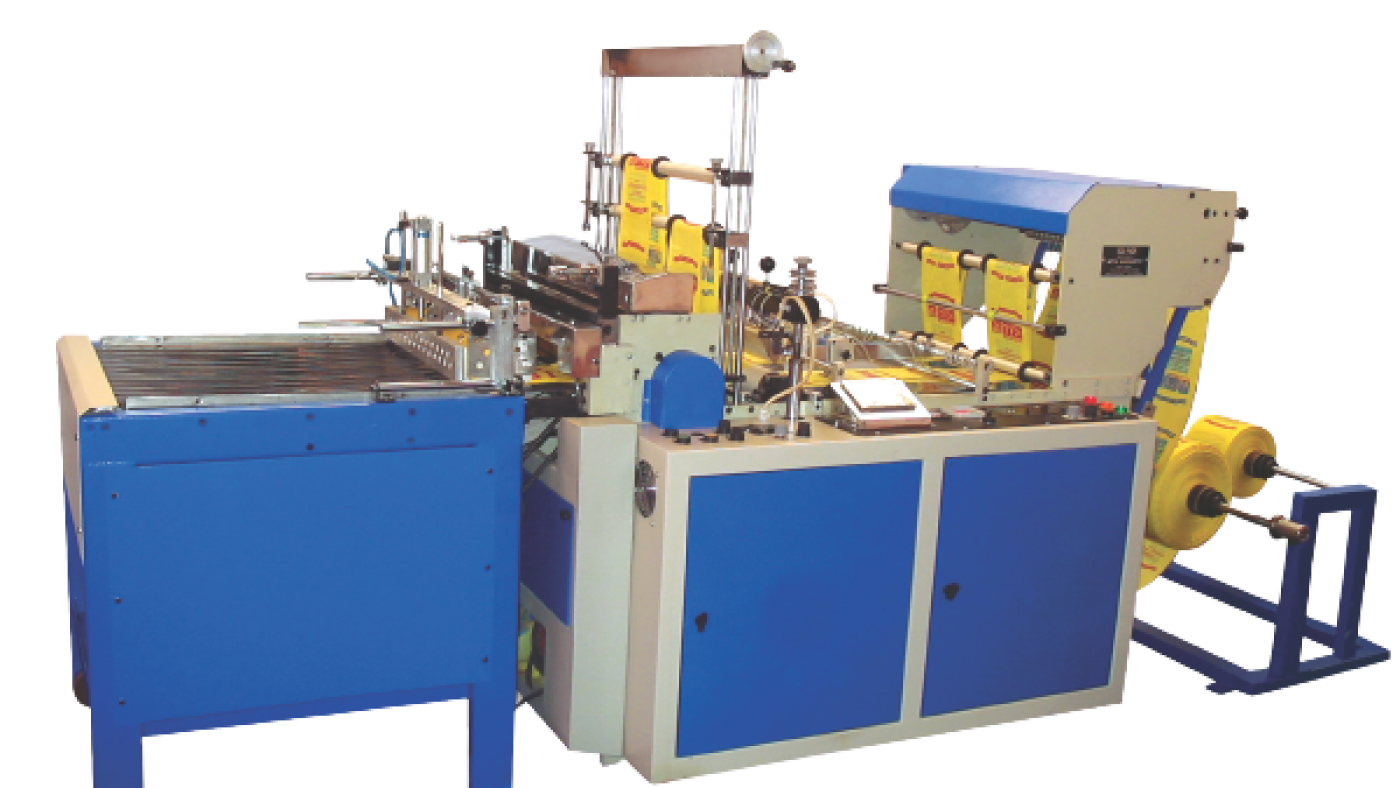

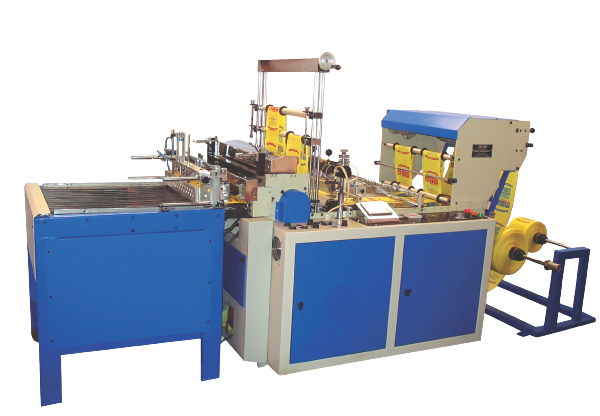

3. Bag Making Machines

(Note:- We only manufacture this type of machine)

Bag making machines convert plastic films into finished bags by cutting, sealing, and folding them into various shapes and sizes. There are multiple types of bag-making machines depending on the type of bags produced:

a. Bottom Seal Bag Making Machines

These machines create strong, durable bottom-sealed bags used for packaging heavy items. The bottom seal ensures structural integrity, making these bags suitable for weight-bearing applications.

Key Features:

- High-speed automation for large-scale production.

- Customizable bag sizes.

- Ability to handle different plastic film types.

Applications:

- Garbage bags

- Industrial packaging bags

- Heavy-duty grocery bags

b. Side Seal Bag Making Machines

Side seal machines cut and seal bags at the sides, making them ideal for lightweight packaging. They are widely used in industries where product display through packaging is important.

Key Features:

- Precision cutting for clean and sharp edges.

- Adjustable width for custom sizes.

- Cost-effective production with minimal waste.

Applications:

- Garment bags

- Flour and bakery packaging

- Medical and hygiene bags

c. Pouch Making Machines

Pouch making machines are designed for specialized plastic packaging, often used for food or powder products. These machines create center seal pouches and three-side seal pouches, which are becoming increasingly popular due to their convenience and branding appeal.

Key Features:

- Multi-layer sealing for enhanced durability.

- Ability to create different pouch styles.

- Free moving multiple sealers for better sealing strength.

Applications:

- Detergent powder pouches

- Food or biryani pouches

- Paper E-Commerce bags

4. Laminating Machines

Laminating machines enhance the strength and durability of plastic films by bonding multiple layers together. This process improves the barrier properties of packaging, protecting contents from moisture, air, and contaminants, making it ideal for perishable items.

Key Features:

- Multi-layer bonding for extra protection.

- Customizable laminating thickness.

- High-speed processing for mass production.

Applications:

- Vacuum-sealed food packaging

- Pharmaceutical packaging

- High-barrier industrial packaging

5. Recycling Machines

With growing environmental concerns, plastic waste recycling has become essential. Recycling machines process used plastic bags into reusable granules, reducing plastic waste and promoting sustainability. These granules can then be used to manufacture new plastic bags, contributing to a circular economy.

Key Features:

- Plastic sorting, shredding, and melting functions.

- Reduced energy consumption for eco-friendly operations.

- Output in the form of reusable plastic granules.

Applications:

- Reprocessing plastic waste into new film

- Producing eco-friendly bags

- Creating recycled packaging materials

Conclusion

Choosing the right plastic bag machine depends on production requirements, material type, and application. Mita Machinery Pvt Ltd provides cutting-edge solutions in plastic bag manufacturing, ensuring efficiency, quality, and sustainability. Whether you need high-speed bag production, custom printing, or eco-friendly solutions, we offer a diverse range of machines tailored to your needs.

Interested in upgrading your plastic bag manufacturing process? Contact Mita Machinery today to find the perfect solution for your business!

Share:

Hitesh Varyani

Technical Consultant

A results-driven technology consultant specializing in IT strategy and software solutions, enabling businesses to optimize processes and achieve measurable growth. Skilled in aligning technology with business objectives to deliver sustainable, high-impact results.

Categories

Latest Posts

-

10 Mar 2025How to Start a Plastic Bag Manufacturing Business in the USA & How Mita Machinery Can Help

10 Mar 2025How to Start a Plastic Bag Manufacturing Business in the USA & How Mita Machinery Can Help -

10 Mar 2025Scaling Your Business with the Right Plastic Bag Manufacturing Equipment

10 Mar 2025Scaling Your Business with the Right Plastic Bag Manufacturing Equipment -

10 Mar 2025Why Leading Brands Trust Mita Machinery for Plastic Bag Manufacturing

10 Mar 2025Why Leading Brands Trust Mita Machinery for Plastic Bag Manufacturing -

10 Mar 2025How Mita Machinery Helped, Increase Productivity by 40%

10 Mar 2025How Mita Machinery Helped, Increase Productivity by 40% -

07 Mar 2025Reducing Plastic Waste with Efficient Manufacturing Techniques

07 Mar 2025Reducing Plastic Waste with Efficient Manufacturing Techniques