How to Start a Plastic Bag Manufacturing Business in the USA & How Mita Machinery Can Help

How to Start a Plastic Bag Manufacturing Business in the USA & How Mita Machinery Can Help

Introduction

Starting a plastic bag manufacturing business in the USA can be a lucrative opportunity, given the high demand across retail, food packaging, and industrial sectors. However, entrepreneurs must navigate regulations, secure financing, and invest in high-quality manufacturing equipment to ensure success. Mita Machinery provides cutting-edge plastic bag manufacturing solutions to help new businesses establish efficient and profitable operations.

Graphic Suggestion: A step-by-step flowchart outlining the process of starting a plastic bag business, placed on the right side.

Market Potential & Industry Statistics

The plastic bag industry in the USA continues to thrive despite increasing regulations. While single-use plastic bans exist in certain states, the demand for biodegradable, reusable, and custom-printed plastic bags is rising.

Key Market Insights:

- The global plastic bag market is expected to reach $30.2 billion by 2028, growing at a CAGR of 3.5%.

- The USA accounts for nearly 20% of global plastic bag production.

- Eco-friendly and compostable plastic bags are projected to grow at a rate of 6% per year.

- The average profit margin in plastic bag manufacturing ranges from 25% to 35%, depending on scale and product type.

Graphic Suggestion: A bar graph showing the market growth of the plastic bag industry in the USA, placed on the left side.

Steps to Start a Plastic Bag Manufacturing Business

Launching a plastic bag business requires a well-structured plan and the right equipment. Here’s how to get started:

1. Conduct Market Research & Business Planning

- Identify your target customers (retailers, wholesalers, or industrial suppliers).

- Analyze demand for custom, biodegradable, or heavy-duty plastic bags in your region.

- Create a detailed business plan, outlining costs, revenue projections, and market strategies.

Investment Estimate:

- Small-scale setup: $50,000 – $100,000

- Mid-sized production unit: $200,000 – $500,000

- Large-scale manufacturing: $1 million+

Graphic Suggestion: A sample business plan structure displayed as an infographic, placed on the right side.

2. Register Your Business & Obtain Permits

- Register your company with the Small Business Administration (SBA) or as an LLC.

- Obtain an Environmental Compliance Certificate to meet regulations.

- Secure necessary zoning and factory permits.

- Ensure compliance with state-level plastic bag regulations (some states have bans, while others encourage biodegradable options).

Graphic Suggestion: A USA map highlighting states with different plastic bag regulations, placed on the left side.

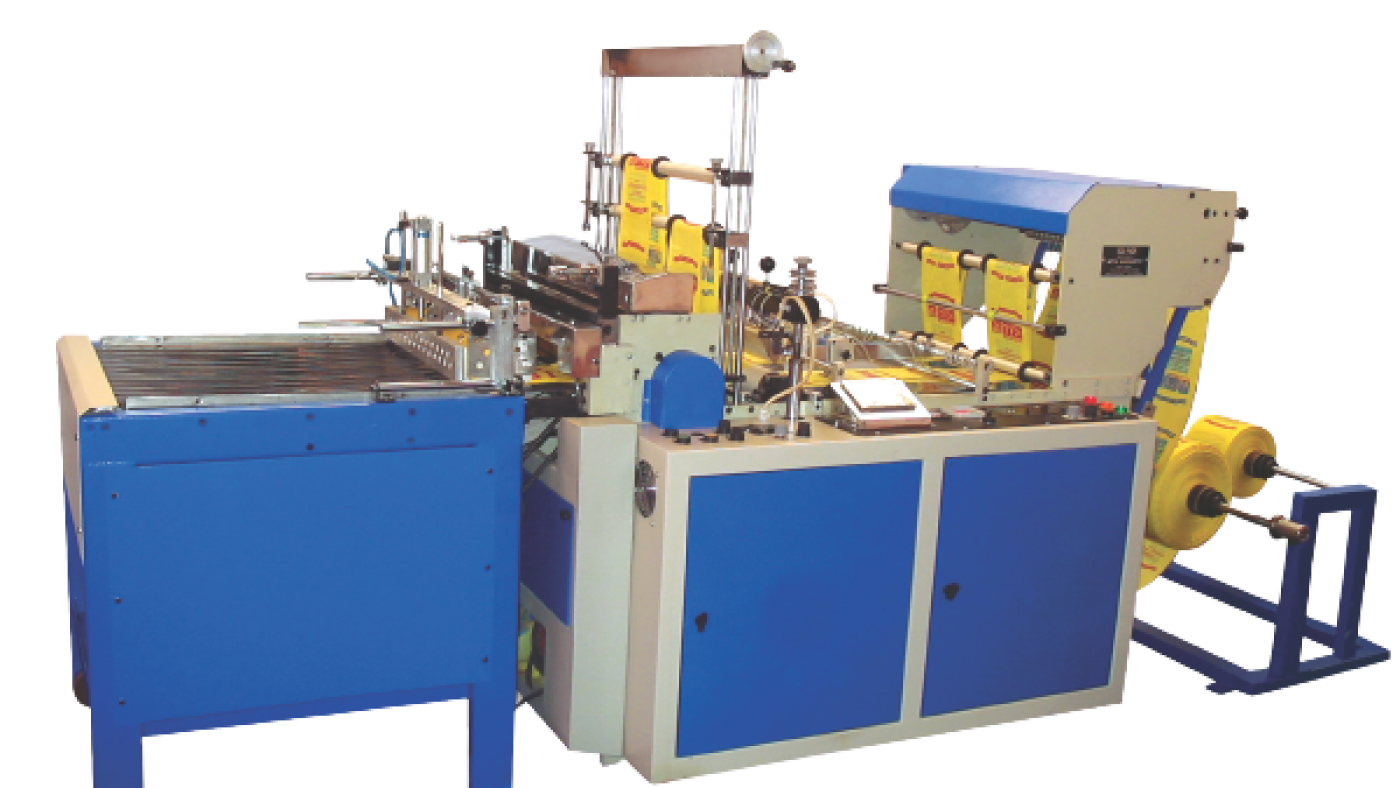

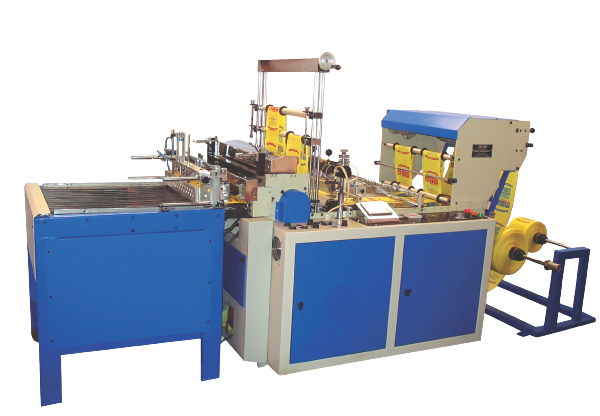

3. Choose the Right Manufacturing Equipment

Investing in advanced plastic bag making machines ensures efficient production and high-quality output. Mita Machinery provides state-of-the-art solutions for:

- Extrusion Machines – Convert raw plastic into high-quality film.

- Bag Making Machines – Produce different types of plastic bags (T-shirt bags, garbage bags, shopping bags, etc.).

- Printing Machines – Customize bags with brand logos and product details.

- Recycling Machines – Reduce waste and improve sustainability.

Mita Machinery Advantage:

- Energy-efficient models to reduce power costs.

- High-speed automation for bulk production.

- Customizable options for biodegradable and multi-layer bags.

Graphic Suggestion: A comparison chart of different plastic bag machines and their production capacities, placed on the right side.

4. Set Up Production & Quality Control

- Secure a factory space of at least 5,000-10,000 sq. ft. for operations.

- Hire skilled labor or train workers on automated production systems.

- Implement quality control measures, including AI-driven defect detection.

- Develop partnerships with raw material suppliers for consistent quality.

Graphic Suggestion: A factory layout showing machine placements and workflow efficiency, placed on the left side.

5. Marketing & Sales Strategy

- Create an online presence through a professional website and B2B platforms.

- Offer customized packaging solutions for different industries.

- Attend trade fairs and exhibitions to connect with bulk buyers.

- Provide eco-friendly alternatives to attract sustainability-conscious businesses.

Sales Channels:

- Wholesale supply to supermarkets and retail stores.

- Direct partnerships with food chains and packaging companies.

- Government contracts for biodegradable plastic bags.

Graphic Suggestion: A marketing strategy infographic highlighting different sales channels, placed on the right side.

How Mita Machinery Helps You Succeed

Mita Machinery not only provides best-in-class plastic bag manufacturing equipment but also offers complete business support, including:

✅ Customized machine solutions based on production scale. ✅ Training & technical support for seamless operations. ✅ Affordable financing options to help new businesses get started. ✅ Sustainability-driven innovations to meet environmental standards.

Conclusion

Starting a plastic bag manufacturing business in the USA requires strategic planning, compliance with regulations, and investment in the right machinery. With the increasing demand for biodegradable and high-quality plastic bags, entrepreneurs have a golden opportunity to enter this market. Mita Machinery provides cutting-edge manufacturing solutions to help businesses scale efficiently, reduce costs, and ensure top-tier production quality.

Are you ready to launch your plastic bag business? Contact Mita Machinery today for expert guidance and high-performance manufacturing solutions.

Share:

Hitesh Varyani

Technical Consultant

A results-driven technology consultant specializing in IT strategy and software solutions, enabling businesses to optimize processes and achieve measurable growth. Skilled in aligning technology with business objectives to deliver sustainable, high-impact results.

Categories

Latest Posts

-

10 Mar 2025How to Start a Plastic Bag Manufacturing Business in the USA & How Mita Machinery Can Help

10 Mar 2025How to Start a Plastic Bag Manufacturing Business in the USA & How Mita Machinery Can Help -

10 Mar 2025Scaling Your Business with the Right Plastic Bag Manufacturing Equipment

10 Mar 2025Scaling Your Business with the Right Plastic Bag Manufacturing Equipment -

10 Mar 2025Why Leading Brands Trust Mita Machinery for Plastic Bag Manufacturing

10 Mar 2025Why Leading Brands Trust Mita Machinery for Plastic Bag Manufacturing -

10 Mar 2025How Mita Machinery Helped, Increase Productivity by 40%

10 Mar 2025How Mita Machinery Helped, Increase Productivity by 40% -

07 Mar 2025Reducing Plastic Waste with Efficient Manufacturing Techniques

07 Mar 2025Reducing Plastic Waste with Efficient Manufacturing Techniques