In today’s highly competitive manufacturing industry, efficiency and productivity are crucial for success. Many companies struggle with outdated machinery, inefficient workflows, and rising production costs. This case study explores how Mita Machinery helped [Client Name] transform its plastic bag manufacturing process, increasing productivity by 40% while reducing waste and operational costs.

Graphic Suggestion: A before-and-after comparison of the client’s production efficiency, placed on the right side.

Before partnering with Mita Machinery, [Client Name] faced several challenges that hindered their growth and efficiency.

Key Issues:

Graphic Suggestion: A visual representation of the key challenges in production, placed on the left side.

Mita Machinery conducted a comprehensive assessment of [Client Name]’s manufacturing process and implemented advanced solutions tailored to their needs.

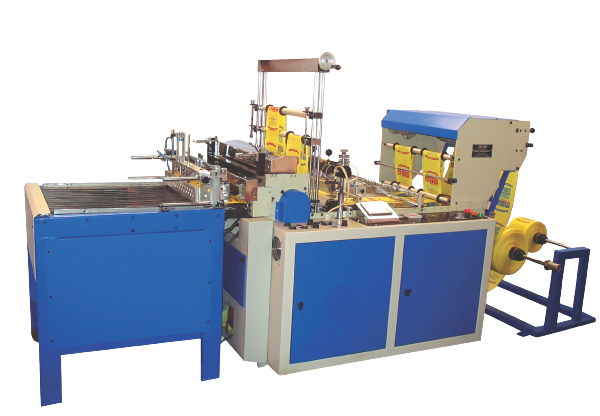

Mita Machinery replaced outdated equipment with cutting-edge, automated plastic bag manufacturing machines that significantly improved efficiency.

Benefits:

Graphic Suggestion: An image showcasing Mita Machinery’s advanced machines in operation, placed on the right side.

To address the issue of material wastage, Mita Machinery introduced precision cutting and recycling systems that optimized material usage.

Advantages:

Graphic Suggestion: A process diagram showing how waste reduction techniques improve efficiency, placed on the left side.

Mita Machinery integrated multi-layer co-extrusion technology, allowing [Client Name] to produce thinner, stronger plastic bags while using fewer raw materials.

Impact:

Graphic Suggestion: A breakdown image of a multi-layer plastic bag structure, placed on the right side.

Traditional manufacturing processes consume large amounts of energy, leading to higher operational expenses. Mita Machinery’s energy-efficient models addressed this challenge.

Results:

Graphic Suggestion: A comparison chart showing energy consumption before and after upgrading to Mita Machinery’s solutions, placed on the left side.

The implementation of Mita Machinery’s advanced technology led to remarkable improvements in [Client Name]’s manufacturing operations.

Key Achievements:

Graphic Suggestion: A bar graph displaying the productivity increase and cost reduction over time, placed on the right side.

Mita Machinery’s commitment to innovation and efficiency has helped [Client Name] achieve unparalleled growth in plastic bag manufacturing. By adopting cutting-edge automation, waste reduction strategies, and energy-efficient solutions, they successfully optimized their production process and increased profitability.

Is your company ready to enhance productivity and reduce costs? Contact Mita Machinery today and take the first step toward a smarter, more efficient manufacturing process.

Hitesh Varyani

A results-driven technology consultant specializing in IT strategy and software solutions, enabling businesses to optimize processes and achieve measurable growth. Skilled in aligning technology with business objectives to deliver sustainable, high-impact results.

MITA MACHINERY is one of the few company in India to offer both LDPE/PP/BOPP BAG making machine and LAMINATE POUCH making machine.

Don’t miss our future updates! Get Subscribed Today!

©2025. Mita Machinery. All Rights Reserved.